Top 10 Safety Violations in 2019 According to OSHA

Safety in the workplace is high priority across the board, especially in the turbulent times. But for many industries the emphasis on safety is around the clock, every day of the year. Safety does not stop. A deeper look into OSHA’s reporting on the safety violations in 2019 can help companies prepare to take an active role in reducing the risk of accidents, violations and fines.

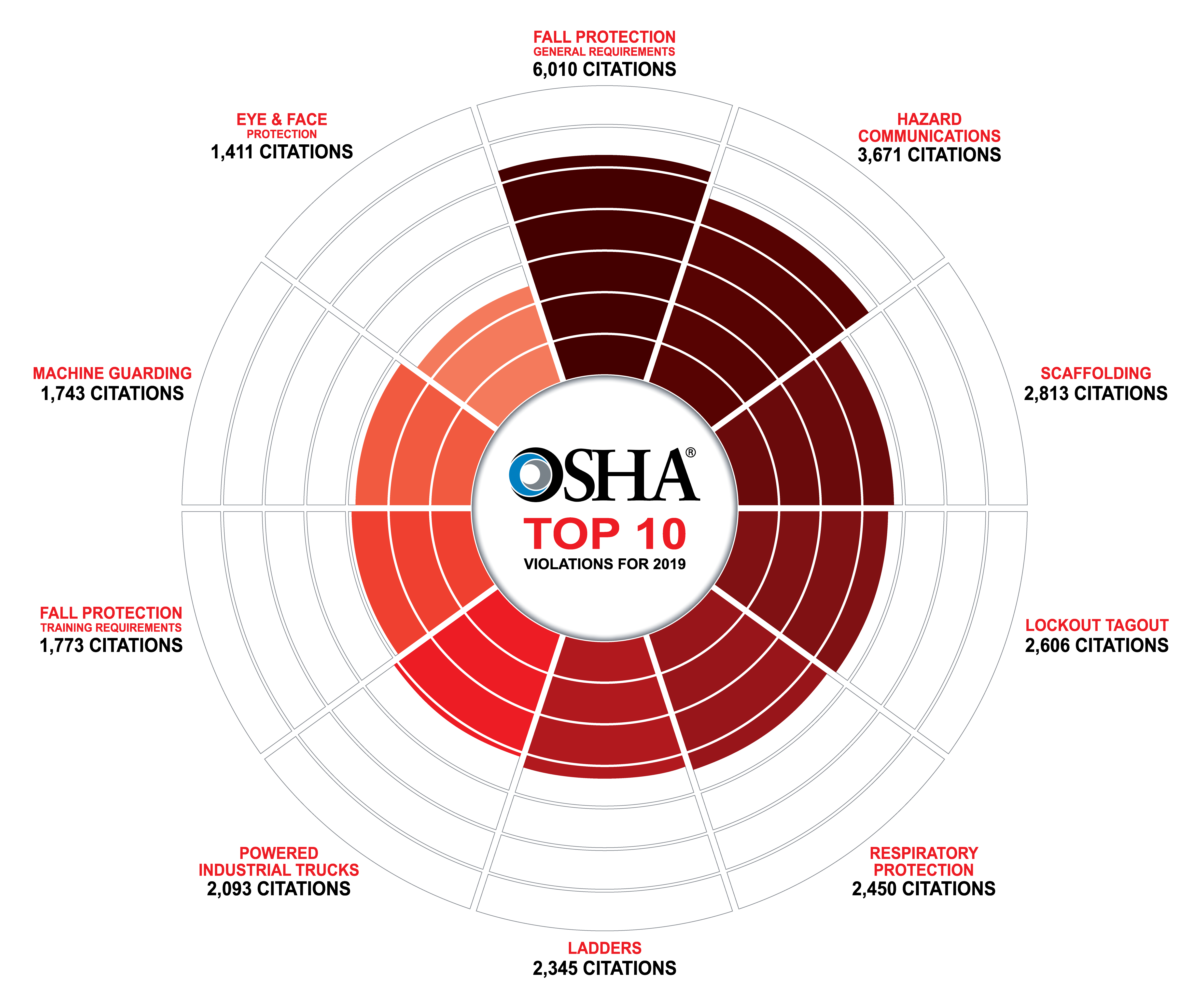

In 2019 overall, OSHA issued approximately 27,000 citations across several categories. Citations and the fees associated can be expensive, slow down projects (sometimes to a halt) and have many other negative impacts to a job site and company.

In addition to the graph above, below we take you through a deeper dive of the top 10 OSHA issued safety violations in 2019.

#10 – PPE - Eye and Face Protection

You might be surprised to learn that 1,411 citations were given in 2019 for inadequate or missing personal protective equipment (PPE) for workers, with emphasis on safety eyewear. OSHA requires employers to ensure that all employees are safe in their work environment, which means providing the necessary equipment or PPE for the job. Thousands of people are blinded each year due to accidents in the workplace, many of which could have been prevented or mitigated with proper eyewear protection.

#9 – Machine Guarding

There were 1,773 citations issued in 2019 for improper or missing machine guarding, which was exposing workers to dangerous risks of injury. OSHA requires that certain pieces of equipment are provided guards and safety devices to protect workers. While these citations were directly linked the machine guards, it’s also important to remember that certain gloves, sleeves and other protective apparel may also be required to work with these machines to provide yet another layer of protection.

#8 – Fall Protection Training

1,773 OSHA citations were issued due to inadequate or no training around Fall Protection. OSHA requires that anyone who will be working at heights receives fall protection training. Falls in the workplace are one of the leading causes of workplace injuries and death, so it gets quite a bit of attention from OSHA who emphasizes proper employee training. Ritz Safety understands the value of training and we offer OSHA Fall Protection training throughout the year at our locations, and can arrange onsite trainings as well.

#7 – Powered Industrial Trucks (or more commonly known as Forklifts)

OSHA has some pretty simple rules for operating a forklift, but for some reason there were still 2,093 citations given in 2019. Forklift rules include things like training, maximum weights, load balancing, speed, and how-to’s for certain situations. The most common violations occur when a forklift tips over and pedestrians being struck. One way to help keep incidents down is to make sure that forklifts and other moving equipment is properly marked and provided with high-visibility reflective strips or vehicle warning lighting to indicate that the machine is in use, both of these solutions can be found at a Ritz Safety near you.

#6 – Ladders

Most ladder issues are a result of misuse or mis-measurement, which tend to be unintentional, but have their fair share of willful misuse as well. Like many others, the 2,345 OSHA ladder violations could have been minimized or avoided with basic training and following guidelines. It’s best to make ladder usage a routine educational topic, to ensure guidelines for using a ladder safely are top of mind. It is also a good idea to inspect equipment as structural defects are also a leading cause of violations.

#5 – Respiratory Protection

Breathing is essential to life but breathing in the wrong air can be life-threatening. OSHA has pretty strict guidelines for what type and how respiratory protection is utilized in the workplace. Many violations stem from organizations failing to establish respiratory protection programs, failing to preform fit testing, and inadequate medical evaluations and training. At Ritz Safety we understand the risks that face the workers respiratory system, so we encourage our customers to visit a store or work with our team to find the right mask for the right environment and the proper fit for your face.

#4 – Lockout Tagout Misuse

2,606 OSHA lockout tagout violations are based on poor documentation, inadequate training, lack of audits, improper processes, and using the wrong devices. Many organizations have inadequate lockout tagout equipment leading to improper training and use, which can easily be mitigated by purchasing the proper lockout tagout devices and leveraging training. The mission of lockout tagout is to properly protect workers from dangerous situations, so proper utilization is essential to providing a safety workplace.

#3 – Scaffolding Violations

Scaffolding violations are high in part because scaffolds are very common in standard construction projects. Millions of workers use scaffolds every year and therefore violations occur, but it’s also important to educate and provide safety precautions for workers. Planking giving away, slips and trips, and falling objects are the three issues that account for over 70% of all scaffolding accidents. Education, audits of equipment, and properly securing every piece are great steps forward in lessening violations.

#2 – Lack of Hazard Communication

OSHA stresses the right for employees to know the hazards and identities of chemicals they are exposed to when working. In addition to hazards, they have a right to know the protective measures that are available to prevent adverse effects from occurring. Most organizations receive hazard communication violations (3,671 in 2019) due to not maintaining a hazard communication plan. Organizations also often fail to label their chemical containers and properly provide SDS sheets from manufacturers. Ritz Safety understands the importance of communication around hazardous materials and has a robust offering of signage, labels, and products for dealing with a chemical spill.

#1 – Fall Protection Requirements & Violations

Coming in at number one, there were 6,010 citations given for fall protection violations in 2019. Ritz Safety takes fall protection seriously and has put a great deal of resources into training, product knowledge, and a vast supply of fall protection products so we can provide solutions for workers at heights. There are times when falls are unavoidable, but they become far less dangerous when proper fall protection precautions are taken into consideration and the proper fall protection equipment is utilized to keep workers safe. Inadequate training in fall protection safety is a leading cause for citations.

OSHA citations can be expensive, a time drain and hurt an organizations reputation, but ultimately citations are just one of the reasons why organizations need to keep their workers safe. The most important reason to emphasis workplace safety is for the workers, the moms and dads, brothers and sisters, sons and daughters, who work day-in and day-out to provide for their families. Protecting the individuals who work within our organizations must be a top priority because every life is worth every precaution.