Electrical shock, extreme heat, ultraviolet, and infrared radiation – these are all of the things that welders deal with. With the number of welding gloves available, which ones do you really need? Let’s chat about everything you need to know about welding gloves…

Shockingly, the most common reason for burns, abrasions, and cuts to welders’ fingers/hands is taking off their gloves to do a hazardous task. Playin’ with fire is no joke and can be extremely dangerous when not wearing the proper equipment.

Not only can welding gloves help protect your hands from electrical shock, but they can also improve grip and abrasion against resistance during welding. The material commonly used in making welding gloves is the top leather obtained from animal hides – cows, goats, deer, and more.

Three things to keep in mind when looking for your ideal welding gloves:

- The type of welding that you engage in – the application primarily depends on the material used

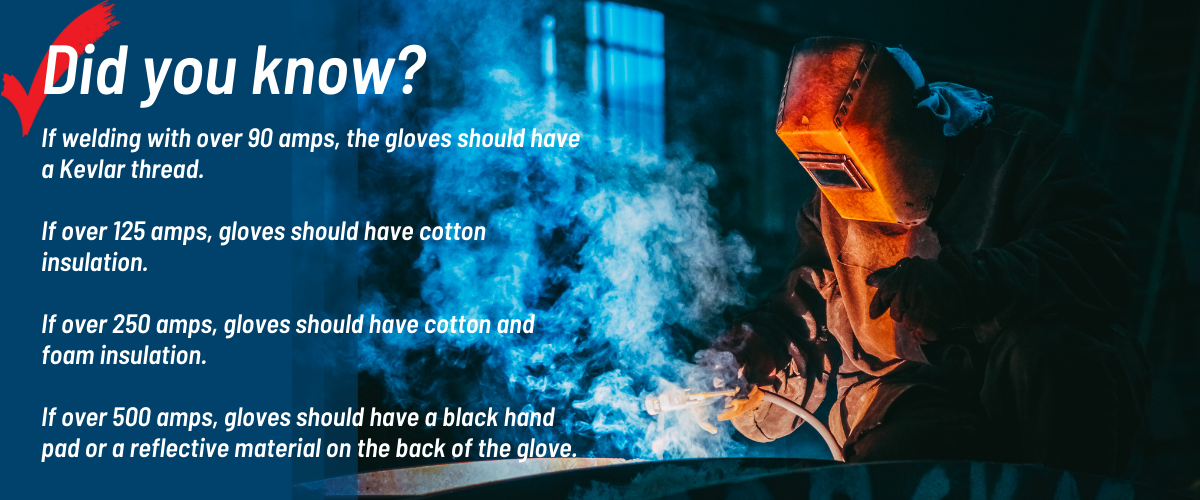

- Type of insulation – good insulators are made of materials such as Kevlar liners, cotton liners, and more

- Hand movement – dexterity levels rely heavily on the type of welding task you perform. For instance, MIG welding requires high protection from heat, while TIG requires gloves that will give welders high dexterity levels

-Mar-21-2022-07-11-42-81-PM.png?width=1300&name=Untitled%20design%20(11)-Mar-21-2022-07-11-42-81-PM.png)

Another thing to keep in mind is the specifications of the glove. Prolonged exposure to excess heat may dry out the gloves, typically wherever the welder grasps the weld gun. Buying gloves that feature extra leather can prevent these problems, such as leather on the thumb, index finger, and the hand’s metacarpus area. Kevlar material also allows you to lengthen the durability of your welding glove.

Explore WELDING GLOVES

Welding is a grueling job, and the gloves need to not only protect the user from their welding process but from the lifestyle of the work environment itself.

-3.png?width=1200&name=Add%20a%20heading%20(2)-3.png)

See standards for Welding, Cutting and Brazing per OSHA here: https://www.osha.gov/welding-cutting-brazing/standards

Welding is an essential component of many industries such as the automotive industry, the construction industry, the aviation industry, and more. Without this form of metalwork, so many things would not exist.

Shop ALL WELDING PRODUCTS